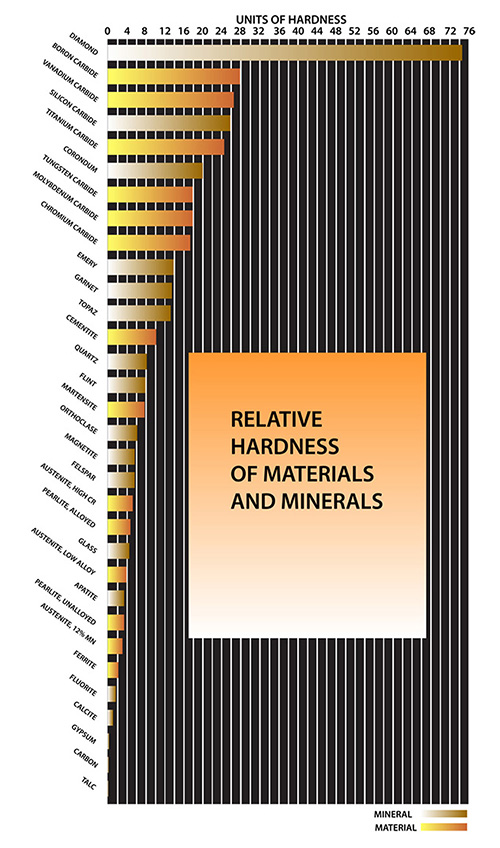

Boima bo lekantsoeng ba Lisebelisoa le Liminerale

-

- 1. Taemane

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emery

- 11. Garnet

- 12. Topaze

- 13. Semente

- 14. Quartz

- 15. Lejoe le thata

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, High CR

- 21. Pearlite, Alloyed

- 22. Khalase

- 23. Austenite, motsoako o tlaase

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Khabone

- 32. Lethathamo

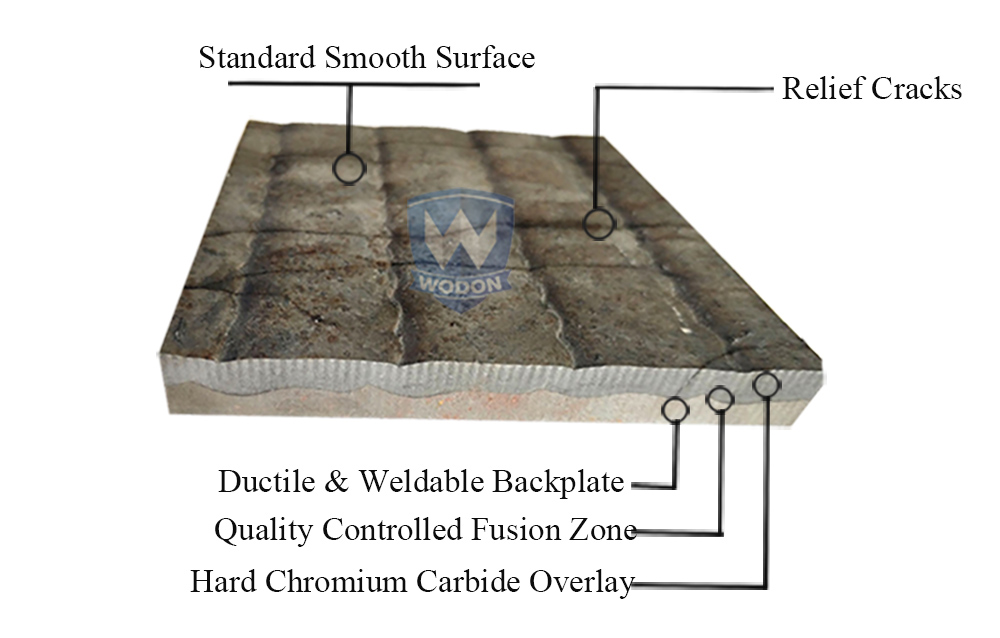

- Wodon li khethehile ho hlahisa poleiti e koahelang ea Chromium carbide, re sebelisa theknoloji ea welding ea arc e kentsoeng ka metsing e nang le litaba tse ngata tsa Cr ho tloha ho 25% ho isa ho 45%. karolo ea carbide bophahamo ba modumo ka microstructure e ka holimo ho 50% le ho thatafala ho fetisisa ea phatsa e thata ke HV1800. mokhoa oa ASTM-G65 A o ka tlase ho 0.16g.

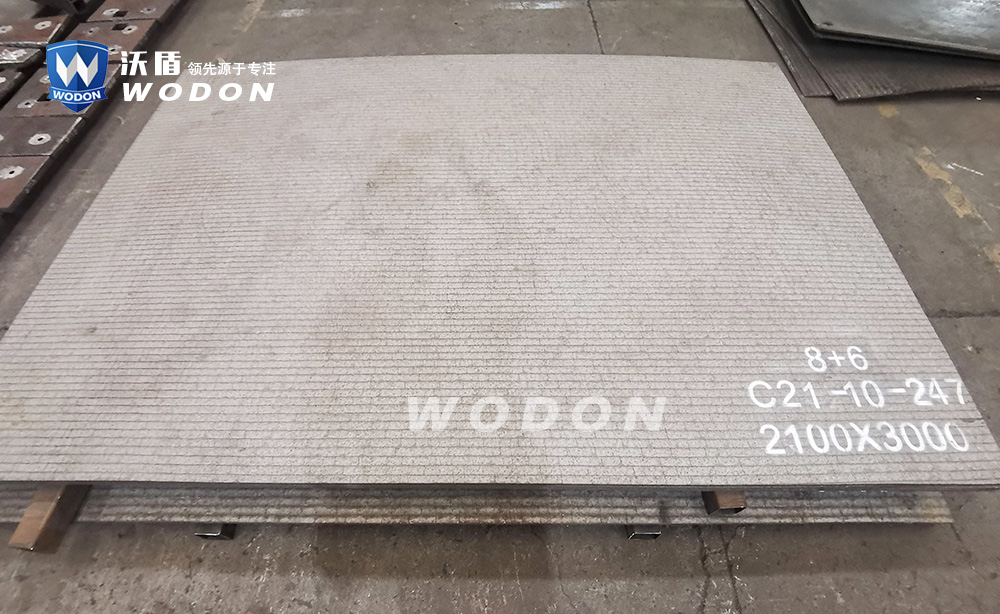

- Chromium Carbide bimetallic plate:

- Mahareng/Ltšepe ea khabone +Alikarolo tse hanyetsanang le brasion →Chromium carbide bimetallic plate e nang le bonding ea metallurgical

- (Q235/Q345B + Chromium Carbide e koaheletsoeng →Chromium carbide bimetallic plate ka submerged arc kapa Open arc welding

- thekenoloji)

- Lintlha:

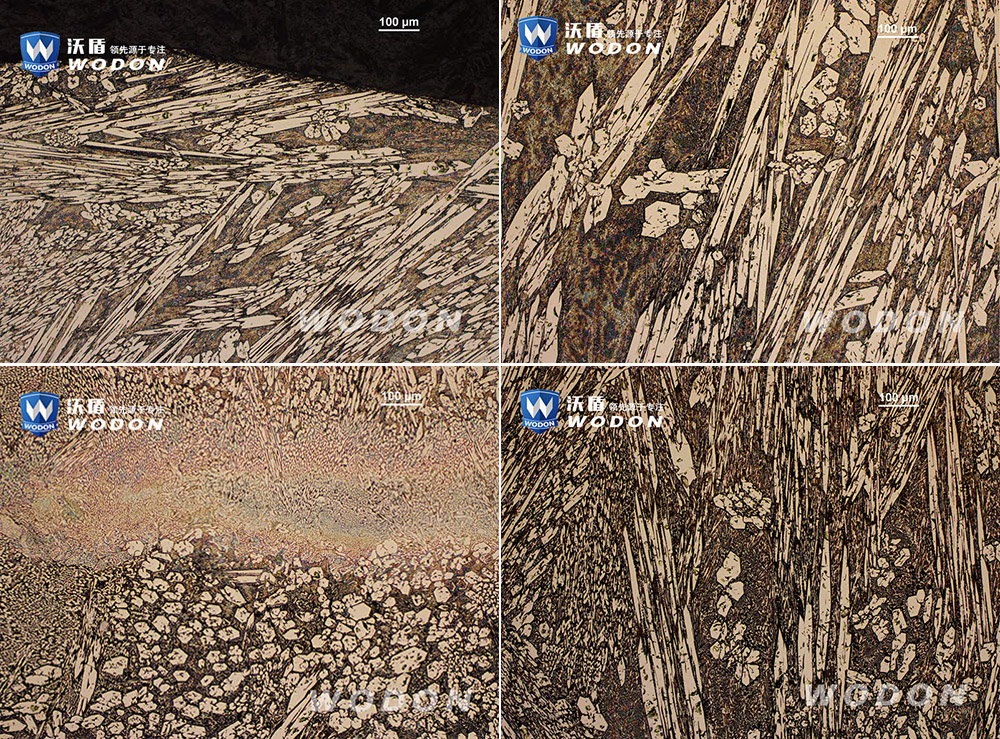

- Lera le hanyetsanang le ho roala le na le palo e phahameng ea likaroloana tse thata tsa chromium carbide. Likaroloana tsena li ajoa ka ho lekana ho pholletsa le lera, ho theha microstructure e matla. Boima ba HRC 58~65'me ho itšetlehile ka botenya ba sekoahelo.

- Lisebelisoa tse ka sehloohong tsa poleiti ea Wodon ke C (%): 3.0 ~6.0 le Cr(%): 25~45. Karolo ena ea lik'hemik'hale e fella ka palo e kholo ea likaroloana tse thata tsa Cr7C3 chrome carbide. The micro-hardness (ho fihla ho HV1800) ea likaroloana tsena ho pholletsa le lera e tla fana ka tiiso ea hore ho na le sebaka se setle sa ho apara.

- The overlay le base plate are metallurgical bonding. Sekoahelo se tla kenella ka har'a poleiti e ka bang 0.8 ~ 1.8 mm, ho fihla ho 350 Mpa litekong tsa rona.

-

- WD1200 ea ho roala poleitie ka sebelisoa bakeng sa applica e matla ea abrasiontions.

- * Sekoaelo sa Chromium carbide se roala poleiti e hanyetsanang

- * Ka theknoloji ea welding ea arc e ka tlas'a metsi

- * Sebopeho sa Lik'hemik'hale: C: 3.0-6.0% Cr: 25-45%

- * Karolo ea molumo oa Chromium carbide Cr7C3 e ka bang 50%

- * Botenya ba lera le sa tsitsang le ka fihla ho 50 mm

- * Ho hanyetsa mocheso ho fihla ho 600°C

- * Sebaka se sa sebetseng sa Lager se sa sebetseng 1400 * 3000mm, 1400 * 3500mm, 2100 * 3500mm

- * Bophara bo betere bo nang le bokaholimo bo boreleli

- * Ho thatafala: HRC58-65(650-720HV)

- Lipoleiti tsena li sebelisoa haholo ho Merafo, Samente, Matla, Mashala, Boema-kepe, Li-turbine tsa Moea le indasteri ea Metallurgis..

-

Nako ea poso: Sep-27-2021