WD-M3 Sebaka se boreleli

Boreleli bo Boreleli

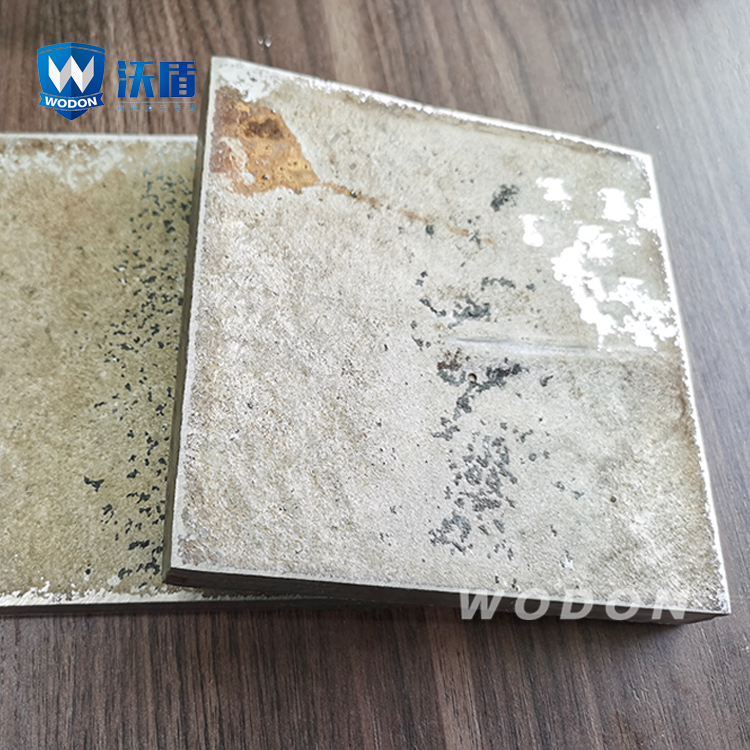

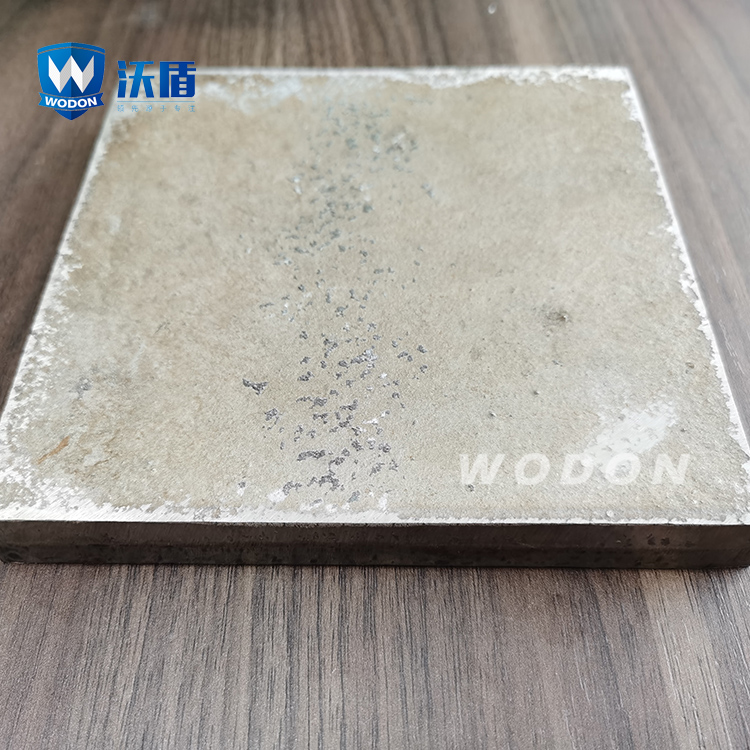

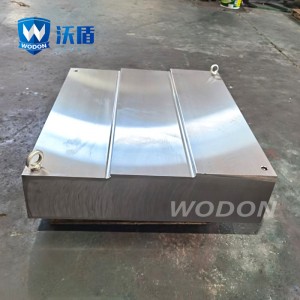

Letlapa le Koaheletsoeng la Chromium Carbide

MOLEMO:

* Sebaka se boreleli, se koaheloa ke pase e le 'ngoe, Ha ho lifaha tse chesellang holim'a metsi

* Sebopeho se sa fetoheng sa microstructure le ho thatafala ho fihlela moleng oa fusion

* Tšebelisano e tlase ea likhohlano

* Abrasion e ntle haholo le thepa e hanyetsanang le tšusumetso

* Mocheso o sebetsang <600℃

* Ka boikhethelo ka sekoaelo se ikhethileng se seng sa makenete

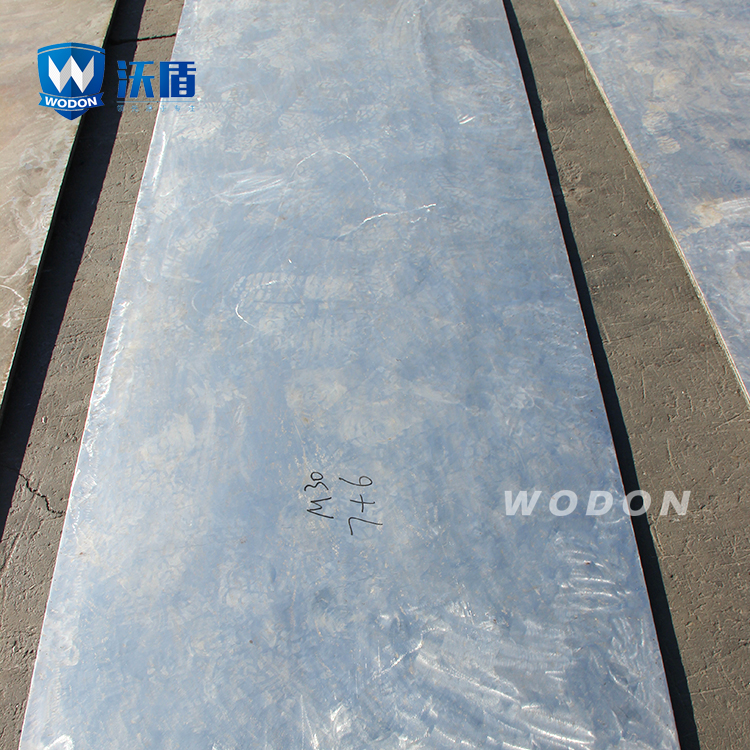

* E fumaneha ka leloala le ka holim'a metsi pele ho belisoa

MOEKETSIMOEKETSI MAEMO

| Kereiti | Sebopeho sa lik'hemik'hale | |||||||

|

| C | Cr | Mn | Si | B | S | P | Nb+Mo+Ti+V+W |

| WD-M3 | 2.0-5.0 | 18-35 | <1.5 | <1.2 | <0.6 | <0.033 | <0.033 | <1.5 |

| WD-M7 | 2.0-5.0 | 18-28 | <1.5 | <1.2 | <0.4 | <0.033 | <0.033 | 7-10 |

| Lintho tsa Motheo | WD-M3 | WD-M7 |

| Lisebelisoa tsa motheo | Q235B | Q235B |

| Karolo e ka sehloohong ea motsoako o thata | Chromium carbide | Chromium carbide + Composite carbide |

| Bophahamo ba carbide ea mantlha (%) | >37 | >37 |

| Overlay Hardness by HV (HRC) | 670 (58) | 670 (58) |

| Teko ea rabara ea abrasion ea weheel ka lehlabathe le omeletseng (g) | <0.15g | <0.14g |

| Teko ea phello ea abrasion (g) | <0.10g | <0.08g |

| Botenya bo tloaelehileng (mm) | 5/5, 6/7, 8/9, 10/11, 12/11, 17/11 | 17/11, 20/11, 24/13 |

| Saese e tlwaelehileng ya poleiti (mm) | 1000*3000, 600*3000 | 600*3000 |

| Sesebelisoa se khothalelitsoeng | Abrasion e tloaelehileng | Ho khopa ho feteletseng |